NEWS

The acceptance of the metal roof branch project of Guiyang Longdongbao Airport Terminal 3 was successfully completed

- Categories:Company News

- Author:

- Origin:

- Time of issue:2021-09-08 08:19

- Views:

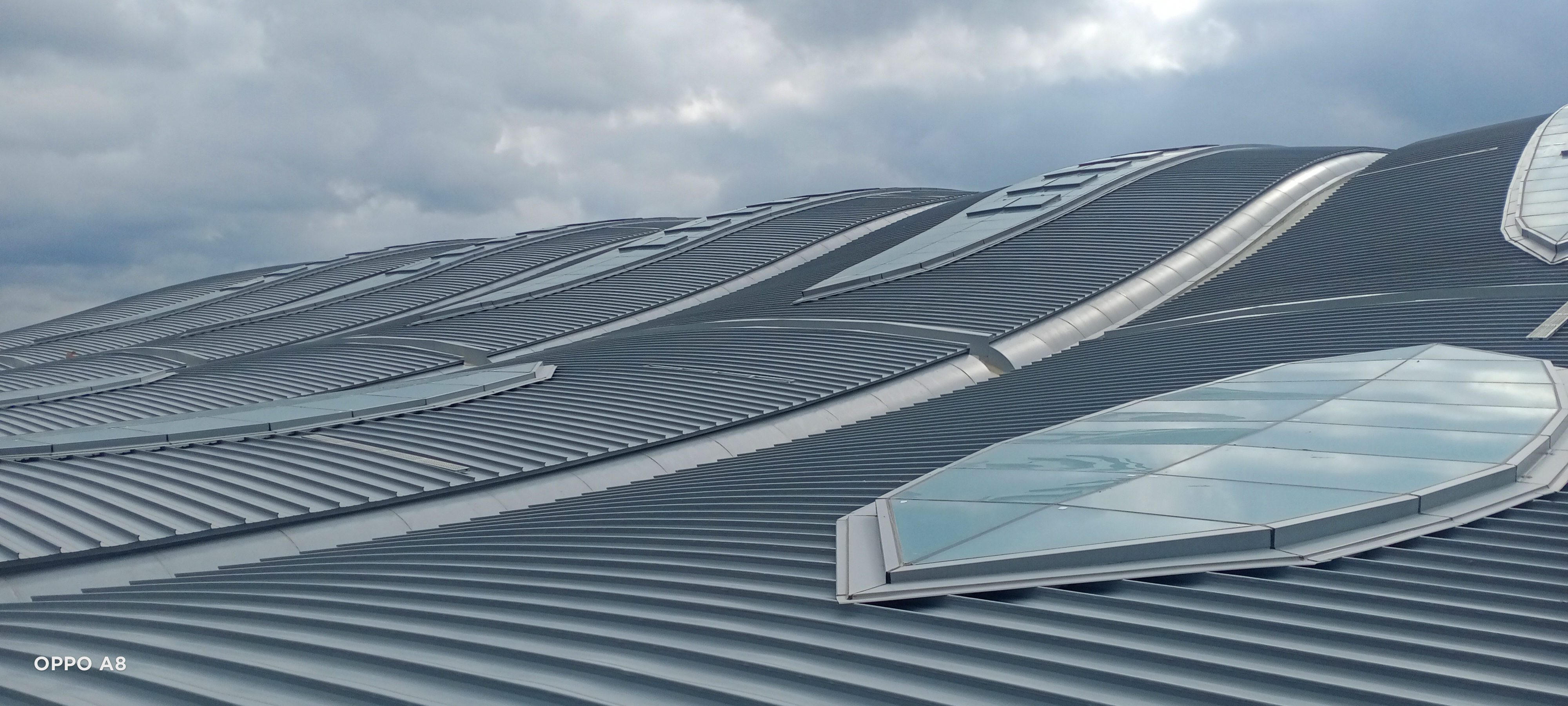

The acceptance of the metal roof branch project of Guiyang Longdongbao Airport Terminal 3 was successfully completed

(Summary description)On the occasion of the golden autumn month, the acceptance work of the metal roofing engineering branch of Guiyang Longdongbao Airport Terminal 3 was successfully completed on August 30. The leaders of Guiyang Construction Engineering Quality Supervision Station came to this project to supervise the whole process of acceptance work. Leaders of Phase III Expansion Project Headquarters and representatives of Terminal Area Project Management Department, Guizhou Architectural Design and Research Institute Co., Ltd., Shanghai Construction Engineering Supervision Consulting Co., Ltd., Zhejiang Dadi Steel Structure Co., Ltd., China Construction Third Engineering Bureau Group Co., Ltd., Guizhou The provincial analysis and testing institute and other project leaders jointly participated in the branch acceptance work. The metal roofing project of Terminal 3 consists of corridors and corridors in Area A, the main building in Area B, overhangs and corridors in Area C, with a total area of 110,000 square meters. The main systems include roof structure system, structural layer system, intelligent skylight system, and siphon rainwater system. The main materials include steel, galvanized plate, vapor barrier film, thermal insulation rock wool, polyurethane rock wool, TPO, stainless steel gutter, honeycomb aluminum plate, aluminum-manganese-magnesium plate and other structural layer materials, with a total laying area of 698,000 square meters. The amount of steel is 3160 tons. The smart skylight system uses electrochromic glass with an area of 6,000 square meters. It is the first high-tech product used in domestic airports. The skylight glass can be used for shading and lighting according to the needs of indoor light. In the construction process, in order to ensure the realization of the construction period objectives, the project management department of the terminal area held several special meetings on tackling fortifications, established a special group, carefully discussed the construction organization plan, and overcome many difficulties. Limited working hours, overcoming the cramped work surface, and making every effort to ensure the established construction period nodes. At the same time, the project department always strengthens the safety management and control of high-altitude operations, so that the metal roofing process can be truly "zero accident" from the start of construction to the end. The project makes reasonable use of BIM technology and innovative construction methods to model the primary and secondary purlins and outer cornices of each working face, and then divide them into several units, which are spliced on the ground as a whole to achieve overall hoisting; Installation and completion of gluing, so that the finished product can be hoisted as a whole and formed at one time, is conducive to improving work efficiency and construction quality, and provides technical support for the completion of the established progress goals. Under the guidance of the leaders of Guiyang Construction Engineering Quality Supervision Station for a long time, under the careful deployment and efficient management of the leaders of the third-phase headquarters, and with the joint efforts of the general contractor, the supervision unit and the participating units, Guiyang Airport No. 3 Airlines The acceptance of the metal roofing branch of the station building was successfully completed.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2021-09-08 08:19

- Views:

On the occasion of the golden autumn month, the acceptance work of the metal roofing engineering branch of Guiyang Longdongbao Airport Terminal 3 was successfully completed on August 30. The leaders of Guiyang Construction Engineering Quality Supervision Station came to this project to supervise the whole process of acceptance work. Leaders of Phase III Expansion Project Headquarters and representatives of Terminal Area Project Management Department, Guizhou Architectural Design and Research Institute Co., Ltd., Shanghai Construction Engineering Supervision Consulting Co., Ltd., Zhejiang Dadi Steel Structure Co., Ltd., China Construction Third Engineering Bureau Group Co., Ltd., Guizhou The provincial analysis and testing institute and other project leaders jointly participated in the branch acceptance work.

The metal roofing project of Terminal 3 consists of corridors and corridors in Area A, the main building in Area B, overhangs and corridors in Area C, with a total area of 110,000 square meters. The main systems include roof structure system, structural layer system, intelligent skylight system, and siphon rainwater system. The main materials include steel, galvanized plate, vapor barrier film, thermal insulation rock wool, polyurethane rock wool, TPO, stainless steel gutter, honeycomb aluminum plate, aluminum-manganese-magnesium plate and other structural layer materials, with a total laying area of 698,000 square meters. The amount of steel is 3160 tons. The smart skylight system uses electrochromic glass with an area of 6,000 square meters. It is the first high-tech product used in domestic airports. The skylight glass can be used for shading and lighting according to the needs of indoor light. In the construction process, in order to ensure the realization of the construction period objectives, the project management department of the terminal area held several special meetings on tackling fortifications, established a special group, carefully discussed the construction organization plan, and overcome many difficulties. Limited working hours, overcoming the cramped work surface, and making every effort to ensure the established construction period nodes. At the same time, the project department always strengthens the safety management and control of high-altitude operations, so that the metal roofing process can be truly "zero accident" from the start of construction to the end.

The project makes reasonable use of BIM technology and innovative construction methods to model the primary and secondary purlins and outer cornices of each working face, and then divide them into several units, which are spliced on the ground as a whole to achieve overall hoisting; Installation and completion of gluing, so that the finished product can be hoisted as a whole and formed at one time, is conducive to improving work efficiency and construction quality, and provides technical support for the completion of the established progress goals.

Under the guidance of the leaders of Guiyang Construction Engineering Quality Supervision Station for a long time, under the careful deployment and efficient management of the leaders of the third-phase headquarters, and with the joint efforts of the general contractor, the supervision unit and the participating units, Guiyang Airport No. 3 Airlines The acceptance of the metal roofing branch of the station building was successfully completed.

Contact Us

Address: #6, Qiannong 1st Road, Xiaoshan District, Hangzhou, Zhejiang, China

E-mail:dadi@cnzjdd.com

- Tel

-

E-mail

- E-maildadi@cnzjdd.com

- TOP

Copyright © Zhejiang Dadi Steel Structure Co., Ltd. All rights reserved. Powered by www.300.cn SEO